Which touch technology is the right one?

Not all touchscreens are the same. Although many consumers consider the iPhone to be synonymous with touch, there are, however, numerous differences to consider. Especially for industrial applications, the various technologies should be examined more closely. Various requirements such as special design, safe and reliable operability, technical features, long availability and a reasonable price have to be accommodated.

Your product is missing an input system? Send us your request.

Which touch technology is the right one?

Not all touchscreens are the same. Although many consumers consider the iPhone to be synonymous with touch, there are, however, numerous differences to consider. Especially for industrial applications, the various technologies should be examined more closely. Various requirements such as special design, safe and reliable operability, technical features, long availability and a reasonable price have to be accommodated.

Your product is missing an input system? Send us your request.

The abbreviation PCAP stands for Projective Capacitive Touch and is the most widely used touch technology today. The touchscreen reacts to touch and projects the associated changes in capacity through the cover glass. The PCAP Touch was developed for industrial use and enables multi-touch operation.

A resistive touchscreen consists of several film and glass layers and reacts to pressure. The pressure of a finger connects the two electrically conductive layers and triggers the actuation. A resistive touch is a more cost-effective solution that is often used for glove operation or even in places with high exposure to electromagnetic interference.

Components and options

Touch systems with cover glass

For the cover glass, a standard float glass is completely customized to the application area of the touch system: anti-reflective coating for better visibility and tempering for robust applications. Design, openings, chamfers or finger recesses can be implemented individually according to customer requirements.

Touch systems with film

For the decorative film, you can choose between a smooth, textured or UV-stabilized (for outdoor use) surface. Design, openings, transparent windows and finishes are implemented individually.

Ball drop test according to UL-60950

To ensure that your touch system always works reliably, we also carry out a ball drop tests on request. In our video we show a ball drop test according to UL-60950 using an industrial touch system with a chemically hardened 2 mm cover glass.

By loading the video, you agree to YouTube’s privacy policy.

Learn more

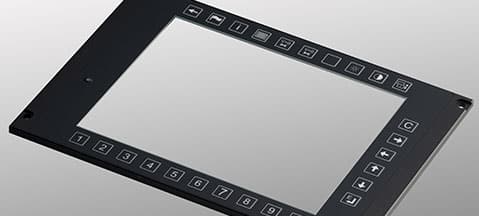

Touch Systems with Membrane Switches

Both resistive and capacitive touchscreens can be combined with a membrane switches. For applications that require haptic feedback when a key is pressed in addition to touch technology, the touch system is expanded to include membrane switches.

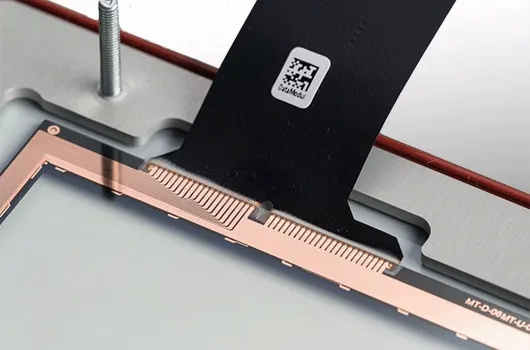

Touch Sensors for Touch Systems

The heart of the touch system is the touch sensor. Together with you, we select the appropriate sensor, capacitive or resistive, and connect it to the remaining components. In the clean room, the touchscreen is bonded to the cover glass or decorative film with a highly transparent adhesive.

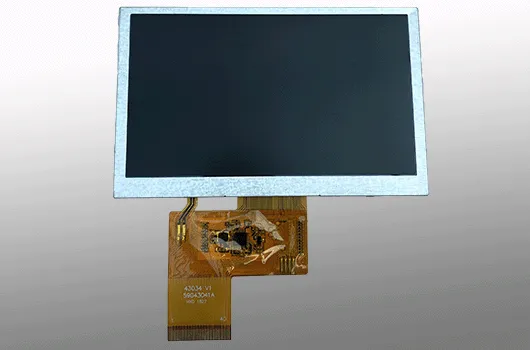

Displays for Touch Systems

There are several influencing factors to consider when selecting the optimal display. Is the control unit used outdoors? Is the display glued or screwed? What resolution must be guaranteed? Should a touch sensor be integrated?

Together with you, we select the appropriate display. The display can be bonded to the glass or touchscreen dust-free with the in-house optical bonding process.

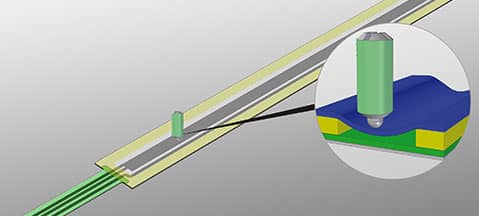

Touch Systems with Optical Bonding

For a brilliant image, we bond touchscreens with displays and cover glasses using the optical bonding process. We rely on two proven bonding techniques: LOCA and OCA bonding.

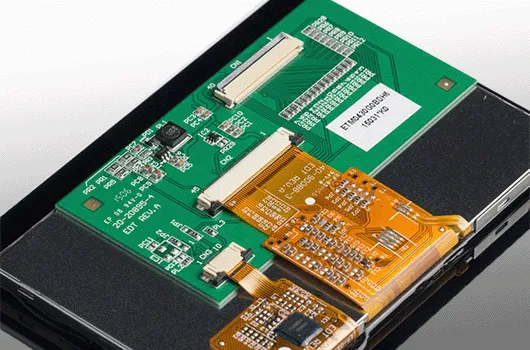

Touch Controller for Touch Systems

The touch controller takes over the entire processing for the touch screen. It can be integrated directly on the connector tail of the touch sensor (chip on tail) or assembled on a separate circuit board.

We will gladly take over the programming for the touch sensitivity settings for you.

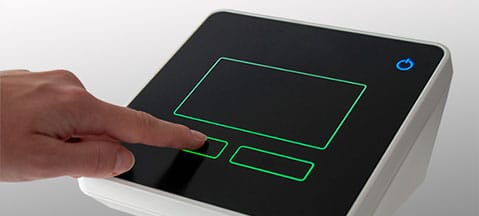

Touch Systems with Housing + Carrier

For optimal mounting of the touch system in your application, we recommend integration on a carrier plate or housing. These give the control unit more stability and simplify installation.

For increased requirements, we supplement the system with an appropriate seal. Individual seal contours can be dispensed with the in-house dispensing machine.

Gaskets for Touch Systems

We protect your touch system against external influences with individual gasket contours. With our in-house dispensing machine, a wide range of different types of gaskets can be dispensed. Dispensed front gaskets in black, white and transparent serve to seal the gap between the housing/front panel and cover glass

More information about our gaskets.

Start your project!

New development or redesign?

We are your partner from prototype to series production.