Compact, cost-effective and endlessly customizable!

No wonder the membrane keypad can be found in almost all areas of use, whether in private households or in industrial applications. Various functions can be easily supplemented with a wide range of additional components: Intensive lighting, complex electronics, modern touchscreen, stable carrier plate or elegant molded keycaps(GT technology).

More information about membrane switches in the Induux Wiki.

Components and options

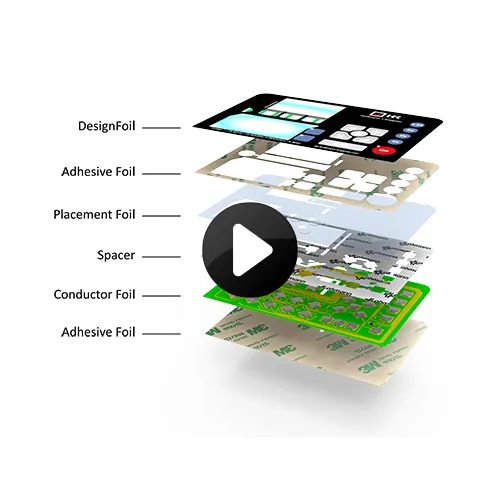

Membrane keypad structure

A membrane keypad consists of polyester films and adhesive layers. The standard structure of our flexible keyboard always consists of 6 individual layers:

- Front foil

- Glue

- Holding film

- Distance film

- Conductor foil

- Glue

The front film or decorative film consists of a resistant polyester film that is printed with a customer-specific design. To guarantee a durable and long-lasting design, we screen print the film from the reverse side.

Molded-on keycaps (GT technology) or embossing enhance the decorative foil and ensure easy finger guidance. Special polyester films with UV protection or antimicrobial properties can be used for membrane keyboards in outdoor applications or for medical technology.

A wide variety of adhesives with different thicknesses and adhesive properties are selected depending on the area of application of the membrane keypad.

The retaining foil fixes the snap disk to the conductor track foil and holds it permanently in position. The spacer foil underneath optimally compensates for the height of the contact springs.

The conductor track foil, also known as the circuit foil, is the actual heart of the membrane keypad. The entire electrical function is located on this level: the printed conductors according to an individual circuit diagram, the assembled contact springs and LEDs.

The conductor track foil can also be replaced by a printed circuit board if required.

Support plates or housings give the membrane keypad more stability and can easily be added on request. The front panel provides stability for the operating unit and can be optimally integrated into the customer’s application.

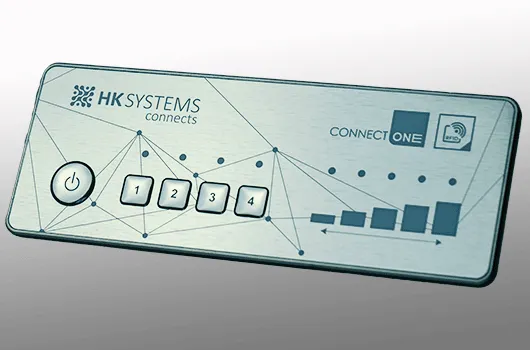

Metal effect

Membrane switches with metal effect: light, durable, elegant!

Go for more individuality with the control unit of your application. A membrane switch is lightweight, reliable, durable and with the right design, it can be transformed into a elegant control unit.

The textured and reflective film surface resembles brushed metal and blends perfectly with other metal surfaces.

Dead front effect

A clean and slim design for your control panel.

Some HMIs control extensive functions and are therefore equipped with many keys, symbols and LEDs.

The so-called “dead front effect” ensures a clean user interface without having to sacrifice functions. A special printing process can be used to hide non-illuminated areas on the surface and display only actively illuminated areas.

Illuminated membrane switches

For the illumination of our membrane switches we use so-called SideLEDs (LEDs emitting light from the side). LED technology combined with a sophisticated switch design, allows us to illuminate large areas and individual keys in a variety of colors. This technology stands out above all with enormous brightness and long service life.

With our lighting technology we reduce installation depth for our customers to a minimum. With a keypad structure of 2.2 mm, the LED technology requires only slightly more space than an EL film. An optional light partition between the individual keys even allows each key to be illuminated separately. The use of bi-color or RGB LEDs also providesa virtually unlimited color selection. Since the assembly must take place on a printed circuit board, its unused back can be used for the assembly of series resistors and ICs or even the entire customer-specific circuit electronics.

Additional features for the decorative layer such as embossing or dispensed key domes (GT technology) are of course still an option. Capacitive keys are also illuminated with our SideLED technology.

Status LEDs

SMD LEDs are used to integrate status LEDs in membrane keypads. These LEDs can be mounted on flexible film as well as on printed circuit boards. For integration on film, the LEDs are glued and held in place on the circuit layer. With an overall height of 0.35 mm, the LEDs can be easily integrated into the flexible assembly. Choose from an extensive color palette between mono, bi-color and RGB LEDs.

Only for areas of application with frequent vibrations, e.g. in vehicles, we advise against glued LEDs on film. Depending on the strength of the shock, the adhesive may come loose and the LED may lose its grip. In this case, we recommend mounting the LEDs on a printed circuit board.

Membrane switches with printed circuit board

A printed circuit board serves as a carrier for the membrane switch and replaces the circuit layer on film used for a flexible assembly. It is made of epoxy FR4 material and can be used as single/ double sided or multilayer PCB. The PCB gives the keyboard assembly more stability and the possibility to add more electronic components, both front and back.

We develop custom solutions with integrated microcontrollers and direct connection to the desired interface.

We specialize in the following interfaces:

- RS232, RS485

- PS/2

- CAN bus

- Modbus

- Profibus, Profinet (Gateway)

- Ethernet

- I2C, SPI

- USB (generic HID)

- Bluetooth

- WIFI

- GSM (data connection via mobile radio)

- Analog digital interface (PWM, 0-10V, 4-20mA,…)

Carrier plates and housings made of metal or plastic

Membrane switches can be mounted on or recessed into carrier plates and housings. Preferably, the carriers are made of aluminum, stainless steel or plastic.

Front panels can be effortlessly integrated into the front of the device or machine by attaching self-clinching fasteners or holes. Customized housings protect sensitive electronics and complete the input system.

The surface of the carrier plate or housing can also be customized to your application: bare, anodized, chromated or brushed. A milled groove for seals ensures that your device is optimally protected from dirt or liquids.

You can also find out more about carrier plates and enclosures from TES Frontdesign, a member of our HK technology network, or from our partner OKW Gehäusesysteme.

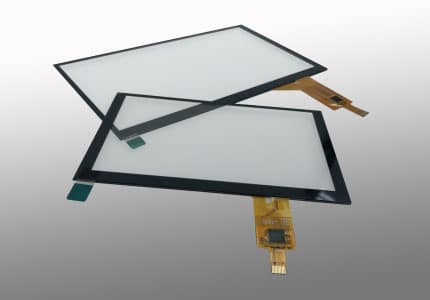

Membrane switches with touchscreen

The tactile feedback of a membrane switch can be combined with a touch-sensitive touchscreen. Both resistive and capacitive touchscreens can be integrated into the switch design. The touchscreen is connected to the membrane switch assembly via an adhesive frame or full-surface OCA bonding.

Membrane switches with slide-in strips

If the same membrane switches is used in different countries, the labeling can be solved using slide-in strips in different languages. So-called slide-in pockets are integrated into the switch assembly for this purpose. Via these pockets, the corresponding slide-in strips can be easily exchanged.

Membrane switches with double contact funcion

High safety requirements for control systems demand maximum reliability of the HMI. For example, a speed function (slow/fast) controlling a crane requires two distinctly different switching functions. Hoffmann + Krippner ensures this so-called double contact function. While the first switching level is activated at a pressure of approx. 7 N, the second level switches only at approx. 13 N. This means that two different actuating forces can be realized in one key.

Dispensed domes on the membrane surface on top of the keys (GT technology) reinforce the tactile feedback of both switching levels.

Membrane keypads with keycaps

We give flat membrane keyboards raised key tops. This allows you to feel where the buttons are even when operating blind. To do this, we apply a dome-shaped, high-gloss plastic compound to the foil surface in the exact position above the buttons. Our GT technology (GT = casting technology) gives the pre-printed design an additional elegant glossy look.

Advantages of our GT technology:

- Extremely high mechanical resistance

- Pressure marks caused by hard objects “heal” without leaving any residue

- Creative design options, e.g. via company logos, displays, LEDs

- User-friendly feel with optimum finger guidance

- Good tactile feedback

Membrane keypads with embossing

In addition to GT technology, foil surfaces up to 0.4 mm high can be embossed for optimum finger guidance. For membrane keyboards with embossing, the decorative foil is formed into the desired shape using appropriate tools, a vacuum and temperature.

You can choose from the following embossing forms:

- Surface embossing

- Frame embossing

Improved technology for less EMI radiation!

For some years now, electronics has evolved to the point where:

- almost no more radiation is emitted due to improved components and design rules in the configuration and PCB layout

- Newer displays do not produce significant radiation

- Control electronics of capacitive touch systems are already radiation-minimized

This means that subsequently added EMI shielding is hardly needed nowadays due to the further development of technology.

EMI shielding

Integrated shielding prevents radiation generated in the device from penetrating to the outside and affecting surrounding devices and interfering with their function. The penetration of external interference radiation into the interior of the device is also prevented by the EMI shielding.

To make our input systems electromagnetically compatible, an electrically conductive layer is integrated into the assembly of the membrane switch. For this purpose, a polyester film is printed with silver polymer and insulation over its entire surface, and one or more contact areas are printed with graphite. The EMI shielding is contacted via a separate connector, e.g. to the ground connection of the device.

For integrated displays, the radiation that occurs must be collected by transparent conductive layers. Thin metal grids cast into Plexiglas or conductive vaporized films or filter discs are suitable for this purpose.

Sealed membrane switches

To ensure that no water or dirt can penetrate into the interior of the device, we use precisely dispensed gaskets. For this purpose, we use silicone-containing, silicone-free or conductive sealing materials.

Sealing of cable outlets is also possible. By spraying the cable outlet with silicone, no water or dirt can get into the inside of the membrane keypad.

More information about our gaskets.

UV protection for membrane switches

For devices that are exposed to UV rays in outdoor use, among other things, we recommend a UV-stabilized polyester film. This special film material prevents discoloration and fading colors.

The UV-stable film has a slight yellow tint. Therefore, color deviations may occur.

Antimicrobial film surface – hygienic for life

For hygienically demanding environments such as in medical and dental technology or in the food industry, we offer a specially developed antimicrobial film for the sustainable protection of membrane keypads against bacterial contamination.

This innovative film material combines

antimicrobial properties with a durable surface. The antimicrobial protection is directly integrated into the textured hard coating. This ensures an even distribution of the antimicrobial agent over the entire surface of the keypad, for its entire service life.

When microorganisms come into contact with the film surface, their cell walls are penetrated by the film’s protective agents. Cell functions are interrupted, and cell growth and reproduction are prevented.

FAQ: Frequently asked questions about membrane keyboards

Membrane keypads offer a high degree of customization. Size, shape, print, surfaces, lighting, connection options can be

can be freely customized. Transparent windows for displays, integrated LEDs or embossed key surfaces are also possible. So

creates an input system that fits perfectly into the design and functionality of your product.

Design:

The top layer of the membrane keypad, the front foil, is screen printed. A wide range of RAL-classic colors is available for this purpose,

Pantone or HKS to choose from. Special colors according to the customer CI, a disappearing effect or a metal look with reflection are possible.

also possible.

Mechanics:

The size and shape of the membrane keypad is fully adapted to the design of the device. Button sizes and positions, installation and

Fastening options and even tolerance specifications can be customized.

Electronics:

In addition to the snap domes for the buttons, LEDs can also be integrated for individual lighting. The circuit diagram and the

Connection (cable, plug, number of poles) of the membrane keypad can also be customized. An integrated electronics assembly on a

Printed circuit board is possible.

Haptics:

In addition to different surface textures on the front foil, additional embossing (surfaces, frames, symbols) or GT domes can also be added to the front foil.

Improve user-friendliness.

Membrane keypads consist of several resistant polyester layers. Depending on the structure and material, they achieve several

million actuation cycles per button. The closed surface provides reliable protection against mechanical wear, dust and dirt and

ensures constant functionality over many years.

Yes, membrane keypads are particularly resistant to environmental influences due to their closed surface. Depending on

The products can be manufactured to protection classes such as IP65 or higher and are therefore resistant to dust and moisture. The used

Polyester films are also resistant to many cleaning agents and disinfectants. This is why membrane keypads are also

Ideal for hygienic environments, such as food or medical technology.

Yes, membrane keypads can be designed to work reliably outdoors. UV-resistant

and temperature-resistant materials are used. In addition, protection types and temperature suitability can be individually adapted so that

the keyboards remain reliably functional at operating temperatures of – 40 °C to 70 °C. Sufficient edge bonding, special

Adhesives or additional seals make a membrane keypad ready for outdoor use.

GT technology is a process developed by Hoffmann + Krippner to produce a dome-shaped, high-gloss plastic material with a high gloss finish.

onto a film surface. GT stands for casting technology. The GT domes are mainly applied to key surfaces,

to improve tactility and enable optimum finger guidance (for blind operation). The plastic mass is extremely

Resistant to mechanical influences. Pressure marks caused by hard objects can “heal” without leaving any residue.

Hoffmann + Krippner has been developing and producing customized membrane keypads “Made in Germany” for decades. Customers benefit

from a unique combination of many years of experience, state-of-the-art production technology and individual advice. Every keyboard

is precisely tailored to the requirements of the application – from design and feel to material selection and special protection and

Hygiene functions. Thanks to our in-house development and production expertise, we can guarantee the highest quality, short distances and

guarantee reliable series production.

Start your project!

New development or redesign?

We are your partner from prototype to series production.