LOCA or OCA Bonding?

We rely on two proven bonding techniques for optical bonding. Liquid bonding, also called LOCA, is used to bond rigid surfaces. Sheet adhesive lamination, known as OCA, can also be used to bond flexible surfaces. Both procedures are performed under clean room conditions to prevent air and dust entrapment.

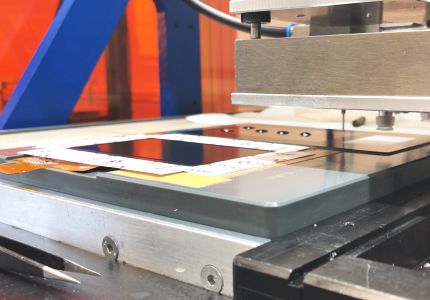

The LOCA Bonding Process

Place touchscreen into device

Check cover glass for impurities

Set and bond liquid glue dots

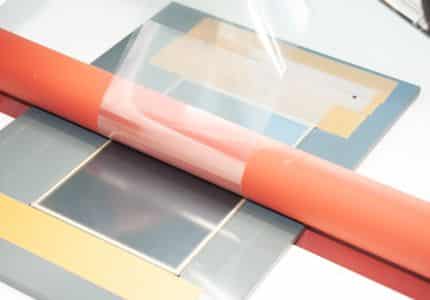

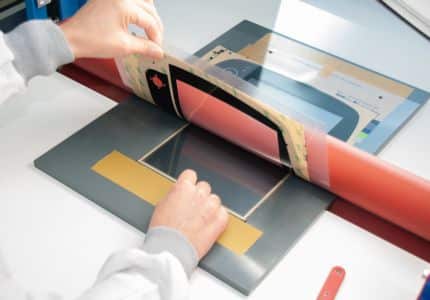

The OCA Bonding Process

Laminate film adhesive on display

Clean components

Adhere decorative film to display

Our Optical Bonding Know-How

Hygiene and care have top priority in optical bonding. Therefore, the optical bonding process takes place under clean room conditions. Special climate and air technology, protective clothing and airlocks ensure consistently high quality.

Liquid bonding (LOCA) in particular also requires in-depth know-how and experience for the optimum casting geometry and adhesive quantity. Each new touch system or display unit requires an individually created casting program. A special technique is used to bond the components to be joined into a single unit.

In lamination (OCA), the challenge lies primarily in bubble-free bonding. The sheet adhesive is applied via rollers and all components are bonded together. Afterwards, possible air bubbles can be eliminated via an autoclave.

Your advantages with optical bonding

Usually, there is an air gap between a cover glass or a touchscreen and the display behind it. This causes the image to lose its brilliance and creates annoying reflections. Optical Bonding fills and eliminates the air gap with a high quality transparent adhesive. This significantly reduces the reflections caused by light refraction.

Optically bonded touch systems are thus also suitable for use in bright environments. The special adhesive technology Optical Bonding ensures a clear view of the display even in unfavorable lighting conditions.

In addition to the brilliant image, bonded systems are much more robust when exposed to temperature fluctuations and mechanical stresses. Otherwise rather sensitive, they can now also be used in industrial applications and in outdoor areas.

This technology also satisfies additional safety aspects. If the glass does break, it does not shatter into a thousand individual parts; instead, the fully transparent liquid adhesive produces only fine cracks that minimize the risk of injury to the operator.

Optical bonding in combination with a capacitive touchscreen offers another advantage. By filling the air gap with a defined medium, namely the adhesive, the sensitivity of the capacitive input can be better adjusted. Otherwise, there is a risk that a mixture of water and air, for example, will accumulate in the air gap and impair the touch functionality.

The adhesive also prevents dirt and moisture from penetrating the gap between the display and the touchscreen or cover glass, thus ruling out possible condensation. So a clouded view of your applications after a long period of system operation is no longer an issue.

Start your project!

New development or redesign?

We are your partner from prototype to series production.