The printing process

Printed electronics is a process in which the application is built additively. The corresponding layout can be printed on different substrates. The electronics are printed using the screen printing process. Fully automated production lines using sheets allow easy and cost-efficient handling. In addition, the company’s in-house electronics manufacturing facility enables the assembly of further electronic components.

Printable materials:

Plastics, synthetic fabrics, metal, glass, printed circuit boards

You need a printed electronics solution? Send us your request.

Printed Electronics from the idea to the product:

- Technical consulting and product design

- Production from prototype to large series

- Screen printing on sheets

- Paste and material selection

- Component assembly in our in-house electronics production

- Plug & Play solutions including electronics unit and housing

Printed Electronics Solutions

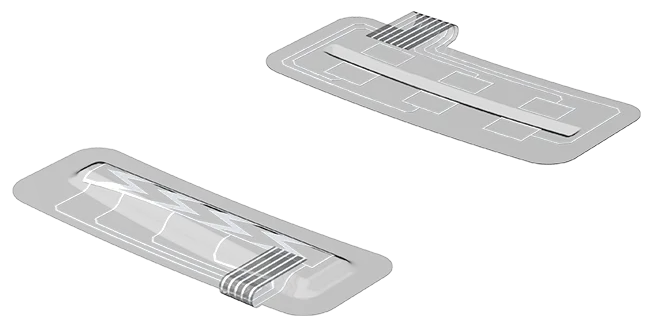

Functional Films: Capacitive Sensor Films

Printed capacitive sensor films save space, are lightweight and can be individually illuminated. It is no longer possible to imagine a vehicle cockpit or household appliances without these sophisticated control units. Just like a touchscreen, the sensor films can be operated intuitively via light touches.

The biggest advantage lies in the individuality. The functional films are printed with the capacitive, translucent control panels entirely according to customer requirements: flexible key shapes and sizes can be applied to different film materials and thicknesses.

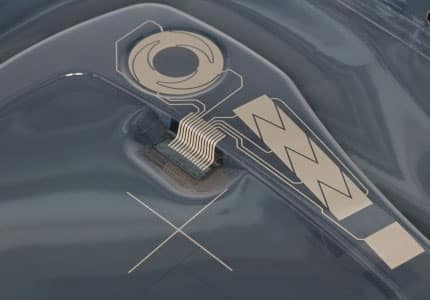

In-Mold Electronics

The in-mold process combines functional films with injection molding technology. The film is inserted into the injection mold and directly back-molded. This process seamlessly combines the functional film with the plastic housing. Special substrates and pastes are used to ensure that the printed functions withstand this deformation.

In-mold electronics combines function with design and is used, for example, in the automotive industry. Vehicle cockpit functions are embedded directly in the dashboard and operated like a touchscreen. Knobs and switches are then no longer necessary.

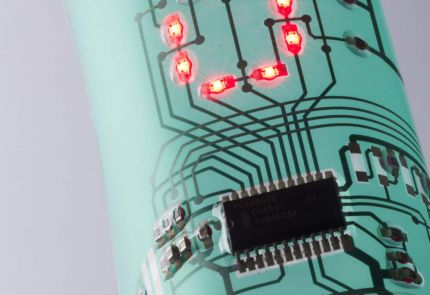

Two technology worlds combined into one: a printed function is combined with conventional electronic components. By contacting and fixating with conductive adhesives, components such as ICs or LEDs can also be integrated on flexible films.

A good example of a long-standing product of this technology is the membrane keypad with integrated LEDs: The circuit is printed, the LED is integrated using adhesives.

Flexible Hybrid Electronics are used where thin, lightweight and flexible electronic units are required. A technology that effortlessly meets the ever-increasing demands: the lightest possible weight, difficult substrates, hardly any space and unusual sizes.

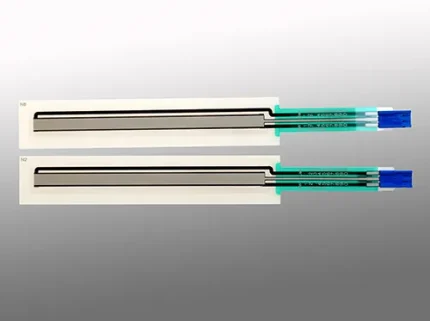

Membrane Potentiometer

Membrane potentiometers are used for displacement and angle measurement. They stand out with precise measurement results, a long service life and a flat design.

Customized sensors

You have not found the right sensor for your application? No problem! We manufacture other sensors with individual functions for you on a customer-specific basis. For example:

- PH Sensors

- Temperature sensors

- Humidity sensors

Start your project!

New development or redesign?

We are your partner from prototype to series production.