The demands on modern input systems are constantly increasing. At the same time, assemblies are to become more compact, durable and energy-efficient. With the new low-temperature soldering technology, we are expanding our production options and taking an important step towards hybrid electronics. Membrane switches in particular offer new degrees of freedom in terms of design, material selection and component integration.

Polyester instead of Kapton

To date, Kapton film has usually been used to assemble SMD components on a foil. Kapton is extremely robust and reliably withstands high temperatures without any problems. But Kapton is also cost-intensive. Low-temperature soldering now enables us to assemble electronic components on inexpensive polyester film. The use of polyester film has a significant impact on costs, particularly for larger surfaces, and makes it a much more attractive solution than Kapton.

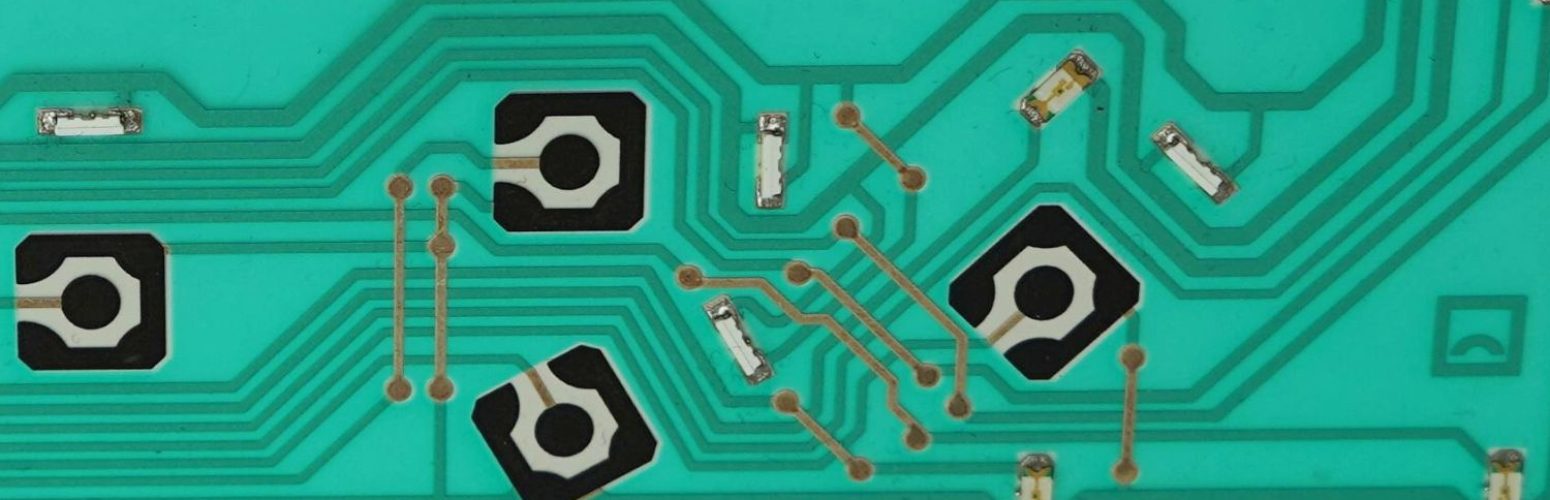

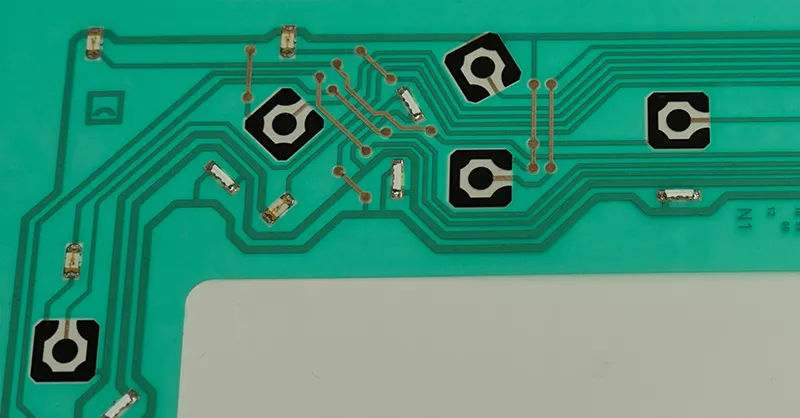

Greater component diversity directly on film

The reduced temperatures open up new possibilities in the assembly of electronic components on foil. Many components that previously could not be soldered onto foils due to thermal limitations can now be integrated without any problems. This means a wider selection of SMD components and more functionality in the same space. Instead of just gluing components, they can now be reliably soldered.

Less structure, more freedom of integration

One of the main advantages of low-temperature soldering is the reduction in the mechanical structure of a membrane switch.

As PCBs were previously used in classic soldering processes, a certain assembly height was automatically specified. SMD components can now be applied to a polyester film just a few micrometers thick and the entire film composite can be made simpler and slimmer. Less installation height means more freedom in appliance design for our customers.

Another new feature is the SideLED lighting technology we have developed.

Thanks to low-temperature soldering, the SideLED solution can now be implemented directly on foil instead of PCBs. This has several advantages: no need for an additional circuit board, less installation space and homogeneous lighting in an even more compact design.

Conclusion

Low-temperature soldering opens up new possibilities for developers and purchasers to implement input systems more compactly, efficiently and economically.

From material savings and greater component freedom to the implementation of our SideLED technology directly on foil are now possible thanks to this enhanced production technology.

If you would like to know how low-temperature brazing can optimize your next operating unit, we will be happy to support you personally.