Product design or industrial design deals holistically with the creation of industrially manufactured series products. In addition to planning and designing (design), the product designer also selects the appropriate manufacturing processes and tools (engineering). And although design and engineering are two very different fields, their combination is essential for making good products. This is especially true for the development of input solutions, control units and electronic assemblies. Only when both worlds are combined can the product ultimately convince the user.

Successful product design is the answer to the existential question: “What can we make of our products to remain competitive? Products are the most important business card of a company. Therefore, it is important to intensively address the design aspect at the beginning of a new development. Effective product design stands for quality, functionality and state-of-the-art technology. In addition, for efficiency, cost savings in development and production, and ultimately for tangible competitive advantages. Only a well thought-out device design, combined with convincing functionalities have a positive impact on usability and even on factors such as sales and customer loyalty.

Product design at Hoffmann + Krippner combines design and engineering. We make sure your devices capture your company’s personality and branding . At the same time, however, we are also considering assembly options and tools. That is why we select the appropriate manufacturing technologies as early as the development phase. After all, fast and cost-effective production is only possible with tooling and manufacturing concepts that are as simple as possible.

In our whitepaper, we show you how you can benefit from tangible competitive advantages through effective product design.

When does design end and mechanics begin?

The key to good product design is to balance design and function: The design supports the function and vice versa. A mature product is one in which every aspect has both a design dimension and a functional raison d’être.

Think of a simple, old-fashioned rocking chair. The design is the shape of the chair. The mechanics are the factors that allow it to support the weight of a person without collapsing and rocking on curved skids. These various aspects must be optimally coordinated so that design and mechanics merge seamlessly. That’s why it’s so important to take a holistic view of design and engineering right from the start.

The same applies to the development of new input solutions. The operating unit must convince at first glance with a high-quality design and a user-friendly user interface. However, effective product design also means matching the compelling design arguments to the mechanics. Only when all technically necessary components harmonize with the desired design requirements can efficient and cost-effective production be guaranteed.

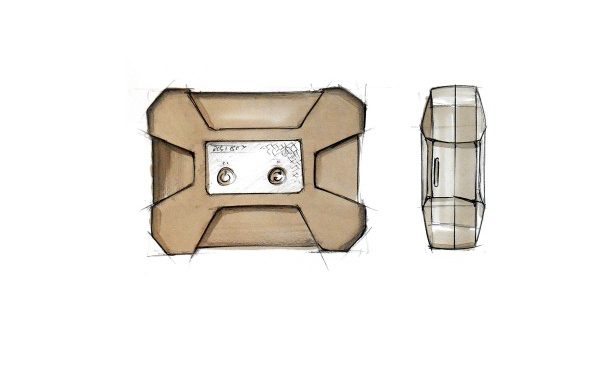

Design:

Modern handheld case with illuminated input field

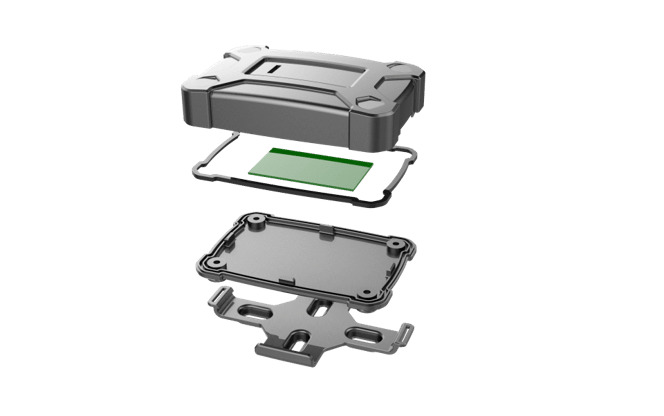

Mechanics:

All assemblies mechanically matched to each other

Product design challenges

Today, people are working on incredibly innovative machines and devices that can be tricky and complicated to design and operate. Just think of one small but very important component of a machine: the control panel. The control unit allows people to interact with the machine. However, it must satisfy both the extensive functions of the machine and optimum user-friendliness. Seemingly simple decisions can be surprisingly subtle and complicated. Product design meets this challenge and answers elementary questions in the process:

- What are the technical and ergonomic requirements?

- Are there any material specifications?

- Which target group needs to be addressed?

- Should a membrane keypad, a sensor foil or a touch screen be used?

- Is lighting necessary?

- How much space can the input solution take up?

- Are specific interfaces and communication protocols required?

- Is a housing, hood or carrier plate required?

- Does the input solution have to withstand certain temperature fluctuations or environmental influences?

- Is certification or testing necessary?

A lot of questions that can be answered just for the component operating unit must be clarified. Now imagine how many more options can have both design and functional impact on the overall final product.

Many of our customers already know what they want. However, they often do not have the necessary resources or know-how to develop their vision. For us, product development is part of a normal working day. With our many years of experience, we transform your idea into a finished product.

At Hoffmann + Krippner, we attach great importance to joint product development with our customers. That is why our engineers and designers are in constant exchange with the technicians and engineers of the equipment developers and manufacturers. This is the only way to end up with a functional, visually appealing and user-friendly product that meets all customer requirements.

We support you in turning unfinished ideas into polished and marketable products.

We relieve you of the burden of product development

Design draft

3D CAD data

Finished product

Our expert team of industrial designers and engineers can take the pressure and complex coordination out of product development. We implement precisely tailored, targeted solutions for you. Our goal is “everything from a single source!”: development, design, prototyping, series production.

Whether a single component, subsystems or complete product solutions, we design and develop products for different industries.

We develop mechanical, electronic and mechatronic systems for you from prototyping to series production:

- Input systems from design to electronics

- flexible printed electronics

- Connected Devices

- Plastic and metal housing

- Printed circuit board layouts

- Software programs

Do you need support with your product development?

Contact our expert right now:

Jens Arend

Product designer

+ 49 +49 69 82 37 247 0