Which touch technology is the right one?

Not all touchscreens are the same. Obwohl für viele Konsumenten das iPhone als Synonym für Touch gilt, gibt es jedoch zahlreiche Unterschiede zu beachten. The various technologies should be examined more closely, especially for industrial applications. Various requirements such as special design, safe and reliable operability, technical features, long-term availability and a reasonable price have to be reconciled.

More information about touch systems in the Induux Wiki

Components and options

Touch systems with cover glass

For the cover glass, a standard float glass is tailored entirely to the touch system’s area of application: a glass surface with anti-reflective coating for improved visibility and a hardened surface for robust applications. Glass printing, perforations, chamfers or finger recesses can be implemented individually according to customer requirements.

Touch systems with foil

You can choose between a smooth, textured or UV-stabilized (for outdoor use) surface for the decorative film. Design, openings, transparent windows and finishes are realized individually.

Ball drop test according to UL-60950

To ensure that your touch system always works reliably, we can also carry out ball drop tests on request. In our video we show a ball drop test according to UL-60950 using an industrial touch system with a chemically hardened 2 mm cover glass.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTouch Systems with Membrane Switches

Both resistive and capacitive touchscreens can be combined with a membrane switches. For applications that require haptic feedback when a key is pressed in addition to touch technology, the touch system is expanded to include membrane switches.

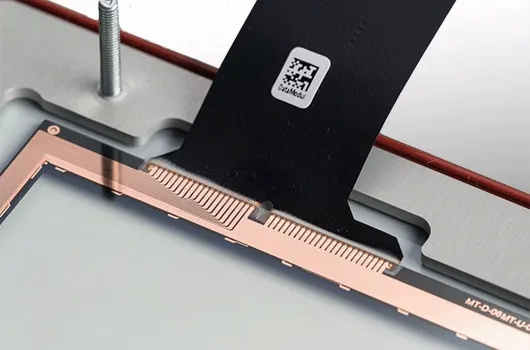

Touch Sensors for Touch Systems

The heart of the touch system is the touch sensor. Together with you, we select the appropriate sensor, capacitive or resistive, and connect it to the remaining components. In the clean room, the touchscreen is bonded to the cover glass or decorative film with a highly transparent adhesive.

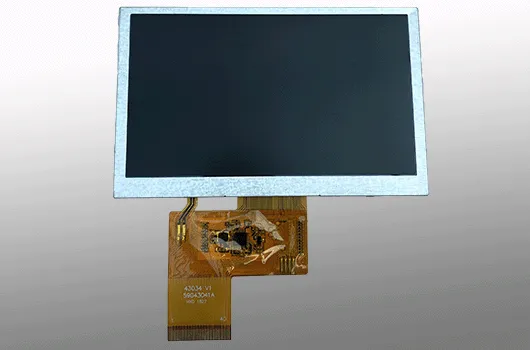

Displays for Touch Systems

There are several influencing factors to consider when selecting the optimal display. Is the control unit used outdoors? Is the display glued or screwed? What resolution must be guaranteed? Should a touch sensor be integrated?

Together with you, we select the appropriate display. The display can be bonded to the glass or touchscreen dust-free with the in-house optical bonding process.

Touch Systems with Optical Bonding

For a brilliant image, we bond touchscreens with displays and cover glasses using the optical bonding process. We rely on two proven bonding techniques: LOCA and OCA bonding.

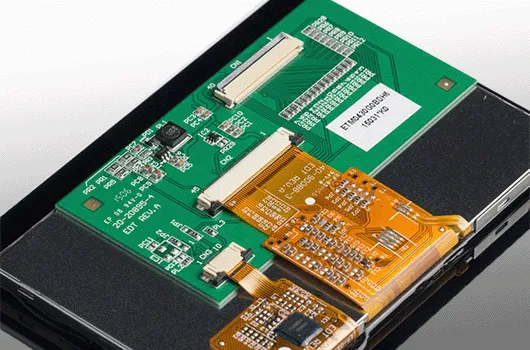

Touch Controller for Touch Systems

The touch controller takes over the entire processing for the touch screen. It can be integrated directly on the connector tail of the touch sensor (chip on tail) or assembled on a separate circuit board.

We will gladly take over the programming for the touch sensitivity settings for you.

Touch Systems with Housing + Carrier

For optimal mounting of the touch system in your application, we recommend integration on a carrier plate or housing. These give the control unit more stability and simplify installation.

For increased requirements, we supplement the system with an appropriate seal. Individual seal contours can be dispensed with the in-house dispensing machine.

Gaskets for Touch Systems

We protect your touch system against external influences with individual gasket contours. With our in-house dispensing machine, a wide range of different types of gaskets can be dispensed. Dispensed front gaskets in black, white and transparent serve to seal the gap between the housing/front panel and cover glass

More information about our gaskets.

FAQ: Frequently asked questions about touch systems

Yes, touch systems can be customized to a high degree. In addition to different glass thicknesses and surface coatings

design customizations, such as glass printing, are also possible. In addition, functions such as multi-touch, gesture control or integrated

lighting can be realized. The result is a touch system that is individually tailored to the requirements and design of the end product.

The robustness of touch systems depends on materials and protective layers. Chemically toughened glass increases resistance to

mechanical and chemical loads. Coatings and seals to industry standards ensure function even under extreme conditions.

extreme environmental conditions.

Resistive touch systems are cost-effective, precise and can be operated with pens or gloved fingers. You react

reliable in the event of soiling or moisture and offer high electromagnetic compatibility, which makes them ideal for industrial applications.

environments.

Yes, touch systems can be designed for outdoor use. In addition, special materials, manufacturing technologies (e.g. optical

bonding) and surface coatings are used to protect against UV radiation, temperature fluctuations or condensation. Also

operability in the rain or with gloves can be ensured by appropriate technical adjustments.

Hoffmann + Krippner combines decades of experience in the development of input systems with state-of-the-art manufacturing technology.

We offer customized touch solutions that meet the highest quality and safety standards. Our strength lies in the individual

consulting, the development of customized concepts and production “Made in Germany”. This results in touch systems that are optimally

your application, industry and design requirements.

Start your project!

New development or redesign?

We are your partner from prototype to series production.