Non-functioning or interrupted supply chains, long waiting times, material bottlenecks: hardly any industrial company is unaffected by the current procurement crisis on the global market. The electronics industry in particular is suffering from the current shortage: a wide variety of components are currently difficult or even impossible to deliver. According to experts, it is not yet possible to predict when this situation will improve noticeably. We are also dependent on the reliable procurement of elementary assemblies, especially for our solutions for input systems in the HMI sector.

Membrane keypad as an alternative to touch solutions

Why and when this consideration makes sense

The problem: components, ICs, displays, touchscreens and other electrical components are missing. Manufacturing technology also plays a role: touch displays require certain chemicals that are difficult to obtain due to the current crisis situation.

Our solution: Create alternatives that can be implemented without far-reaching changes to project planning.

For input systems, this means that membrane keyboards are not affected by the current procurement crisis. All parts and components are currently available without any problems or delays. Of course, at first glance, a touch system is the more modern technology: it is trendy, now also mature and equipped with a number of options.

But what if these options are not feasible in the foreseeable future? Then it helps to ask the right questions rather than simply waiting, postponing or resigning!

When developing new devices or redesigning existing ones, it currently makes a lot of sense to ask yourself the following fundamental questions about the right input system at the start of every project planning:

- Where will my product be used?

- How robust does it need to be against environmental influences?

- Are safety functions necessary?

- How much space is available for the input system?

- How should the input system be connected?

- What role does haptic feedback or finger guidance play?

- What can the operating unit cost?

- What service life must the control unit have?

- Does it have to be a complex touch system or is a membrane keypad perhaps the right choice right from the start?

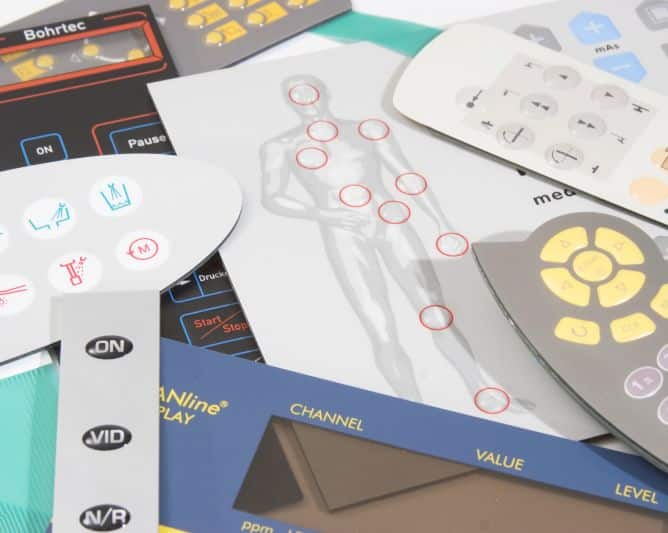

Advantages of membrane switches: durable technology for many areas of application and industries

When it comes to reliable input systems, the use of membrane keyboards can cover virtually all areas of application for many industries. The advantages are obvious:

- Robustness against many, sometimes extreme weather conditions

- Durability: membrane keypad lasts up to 15-20 years

- Cost-effective

- Short-term procurement of all materials possible

- Also available without complex evaluation electronics

And given the current situation, perhaps the biggest advantage is that everything is available in-house at H+K. The components for the production of a reliable, ready-to-use membrane keypad are completely available, as are the development and production capacities.

Membrane keypad instead of capacitive input unit: charging station application example

In this context, a current project example shows very clearly that a complex capacitive operating unit does not always have to be the only solution: The customer had originally decided to use a capacitive keypad for a charging station. After extensive consultation, the decision was made in favor of a membrane keypad. Quite apart from the current delivery difficulties, the possible weather conditions in daily practical use played a particularly decisive role in this case: the charging station had to be able to be operated flawlessly in outdoor use, even in storms, rain, snow and hail. An area of application in which the classic membrane keypad shows its strengths.

Please contact us to find out whether a solution based on the use of membrane keypads is also possible for your application!

Simply send us your message or give us a call on +49 6281 5200 0.