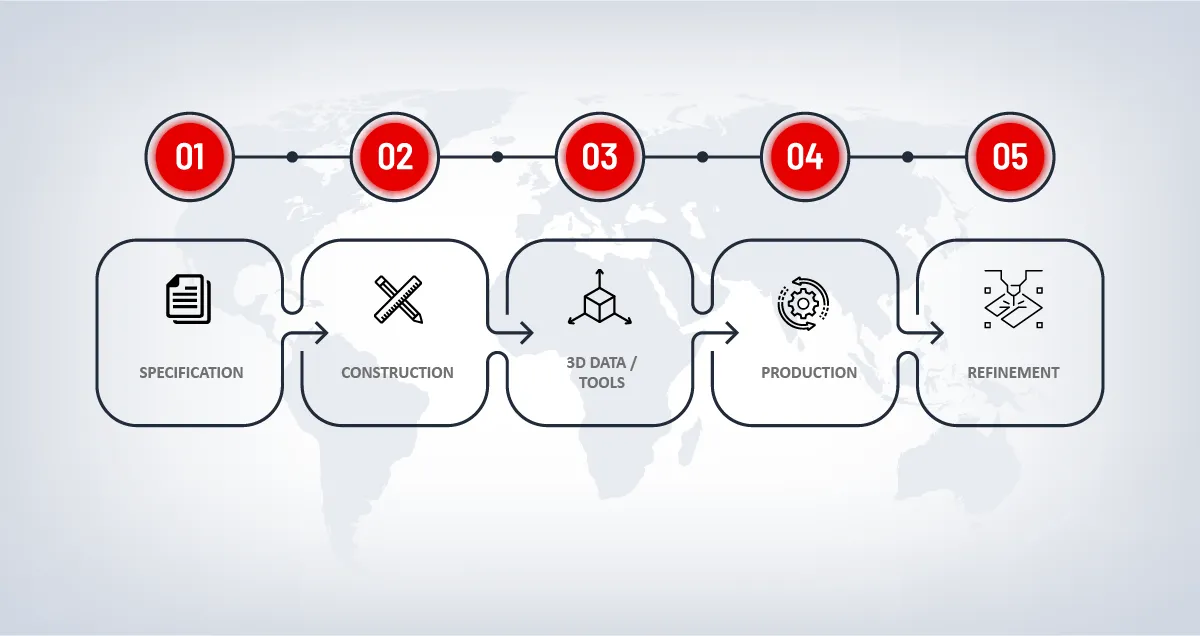

3D printing for functional prototypes and small batches

You would like to turn your idea into a prototype quickly and easily? Within 3-5 working days, we produce prototypes and small series using the 3D printing process. All that is required is your design data as a STEP or STL file.

3D printing is an additive manufacturing process in which one or more materials (usually plastic) are applied layer by layer (= additive) to create a three-dimensional workpiece. The coating application is computer-controlled. Liquid or solid materials are “printed” according to the dimensions and shapes of a CAD file. This manufacturing process allows to quickly and easily produce workpieces, without expensive tools.

More information about enclosures in the Induux Wiki.

Your advantages:

- Quick and easy implementation

- Only 3D data needed, no tools required

- Material density and texture comparable to conventional plastic parts

- Design freedom & customisation

- Optimization possibilities through function integration

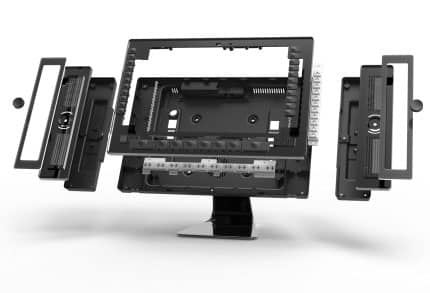

Housing options

3D printed housing

For 3D printed housings and enclosures, we rely on HP’s innovative Multi Jet Fusion 3D printing process. It combines the strengths of the two rapid prototyping processes polyjet and selective laser sintering (SLS). In just a few seconds, individual layers are printed and immediately bonded together. We use the multifunctional polyamide 12 as the printing material.

The printed parts have an almost 100% density and are absolutely comparable with conventionally produced plastic parts.

Certificates:

Biocompatibility

PAH (EU REACH)

UL 94 and UL 746A certification

Composition declaration for toy applications

RoHS-Reach

Housing processing

Openings for displays, switches, cables, knobs or operating elements can be provided individually according to your requirements. Milled recesses provide a protected installation space for your operating front. Threaded holes and studs create optimal mounting options for electronic components and for installation in your application.

Surface finish

Metal housings are given a high-quality finish by grinding, brushing, polishing, scotching or glass bead blasting. Depending on the application, surfaces can be chromated, passivated, anodized or stained for protection.

For harsh environments, we recommend applying a powder coating. The powder-coated metal makes your application especially resistant to shocks, impacts and scratches.

- grinding, brushing, polishing

- chromated, passivated, anodized, stained, and

- powder coating

- paint, coat

Plastic housings can be painted in your corporate color for more individuality. Applying protective coatings, such as an ESD coating, prevents electrostatic discharge.

- ESD coating

- Color paint

Printing

For even more customization, lettering, logos and graphics can be applied to your plastic and metal housing using screen or digital printing.

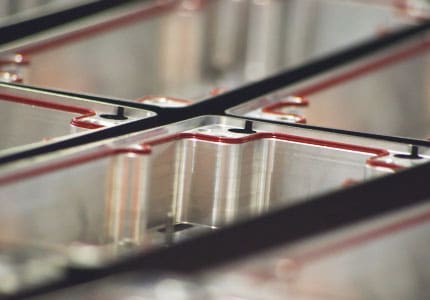

Gaskets for housing

Thanks to our own dispensing systems, single or double beads can be dispensed in customized contours. Silicone-containing, silicone-free or conductive sealing materials provide reliable protection against dirt and liquids.

Arrange free product demo

We will show you all the possibilities during a product demo,

that a housing can offer.